separator systems

For grease, oil, petrol and other separator systems, we carry out regular maintenance with sampling and also offer general inspections with leak tests in accordance with DIN 4040 and DIN 1999. Of course, we also offer you the planning and installation, as well as the sale and delivery - everything from a single source. Please get in touch with one of our contact persons, we will advise you individually on your request.

Mixtures of substances (e.g. emulsions, suspensions or aerosols) are mechanically separated in the separator. The mechanical separation process that takes place in the separator is based on the difference in the densities of the various substances. The goal of separation is to remove one or more components of the mixture of substances (e.g. oil from water, fat from water, petrol from water).

Separators for various substances, e.g.:

- Grease separator.Light liquid separator (petrol separator, oil separator).

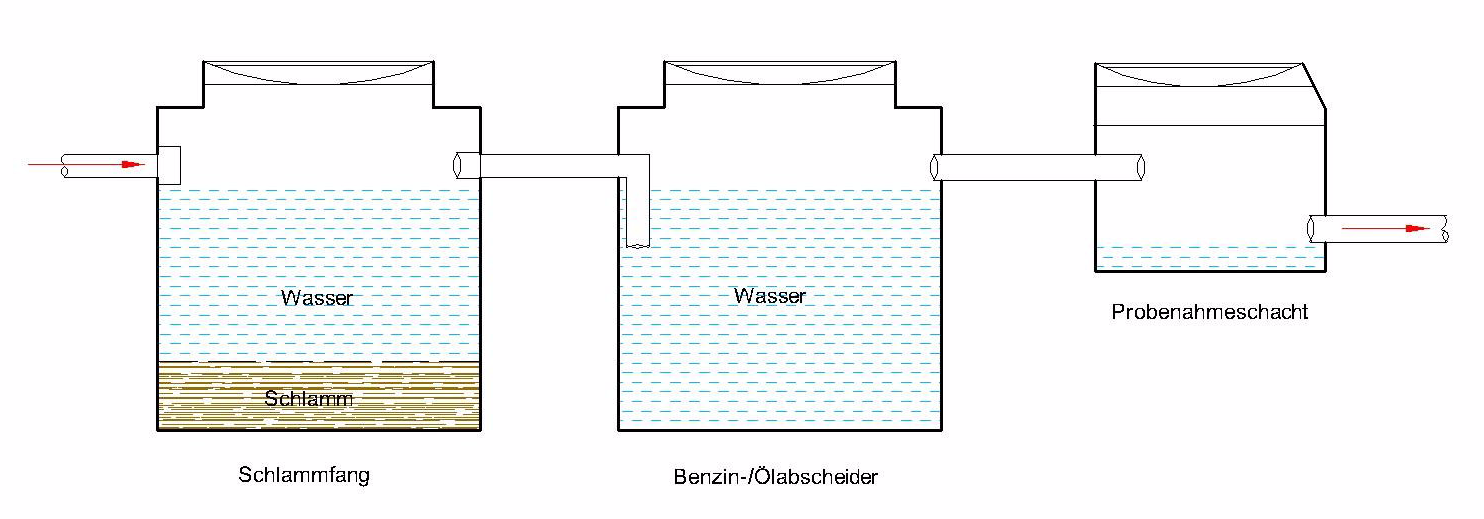

Sketch of the process:

description

The principle of the separator is always the same for the different separators. The mixture of substances to be separated, in this case waste water, flows into the first chamber of the separator, where it is calmed, ie slowed down. From there, the waste water enters the second chamber, where the less dense substances (oil, petrol, grease and other volatile substances) have enough time to float to the surface. These substances remain there until they are pumped out by special companies and disposed of properly. The waste water, separated from the oil, petrol, grease or other substances, can now be carefully removed from below. The waste water is now largely free of the substances to be separated.

We offer you planning and installation, annual maintenance and 5-year maintenance with leak testing of the separators. The necessary certificates of expertise and technical knowledge are available.

Please get in touch with one of our contact persons, we will advise you individually on your request.

fat separator

The principle of the grease separator is the same as described above under separator. The grease separator can be placed inside and outside the house. Fats must be vegetable or animal and partially or fully water-insoluble and saponifiable.

According to DIN EN 1825-2, grease separators are prescribed in the following companies, for example:

- Kitchen businesses (restaurants, hotels, motorway service areas, canteens, etc.) butchers with and without slaughtering meat factories, sausage factories with and without slaughtering slaughterhouses (large slaughterhouses) animal carcasses oil mills and cooking oil refineries margarine factories canned food and ready meal production

Dirty water from e.g.:

- DairiesCheese dairiesFish processing plantsCatering plants that only have rinsing operationsWaste treatment plants

In addition, all waste water with a large part of the fats in emulsified form, ie not separable, is only effectively treated in the separator under certain conditions, which may require further treatment.

For your grease separator, we carry out the maintenance (one year and five years) and the leak test with the necessary proof of expertise and proof of specialist knowledge and the maintenance. We also offer you the planning and installation of a grease separator. Please get in touch with one of our contact persons, we will advise you individually on your request.

light liquid separator

The principle of the light liquid separator (e.g. oil separator, petrol separator) is the same as that already described for the separator. The light liquid separator can only be installed outside the house. Light liquids are not or only very poorly soluble in water and unsaponifiable.

There are two classes of these separators:

Class I: with a maximum residual content of 5 mg/l. You can do this e.g. B. reach with a coalescence separator.

Class II: with a maximum residual content of 100 mg/l. You can do this e.g. B. achieve with a gravity separator.

According to DIN EN 858-2, oil separators and/or petrol separators and/or light liquid separators are prescribed in all companies where oils, petrol and/or other light liquids can get into the dirty water.

Not all light liquids can be separated equally well. In the following tables you can see some substances that can be separated well and less well. In the case of light liquids that are less easy to separate, further measures may have to be taken to separate the light liquids from the waste water.

Sketch of the process:

new text